Nevada

CENTURY LITHIUM ANNOUNCES POSITIVE FEASIBILITY STUDY FOR THE CLAYTON VALLEY LITHIUM PROJECT, NEVADA

FEASIBILITY STUDY HIGHLIGHTS

- Large-Scale Nevada-based Lithium Project: three-phase production plan will generate a life-of-mine average of 34,000 tonnes per annum (tpa) of battery-quality lithium carbonate (Li2CO3)

- Innovative Approach in Processing: patent-pending chloride leaching process combined with Direct Lithium Extraction (DLE), the Feasibility Study is supported by 2+ years of testing at the Company’s Pilot Plant

- Mineral Resource Estimate: Measured and Indicated resources totaling 1,207.33 million tonnes (Mt) at an average grade of 957 parts per million (ppm) lithium (Li) containing 1.155 Mt of Li or 6.148 Mt of lithium carbonate equivalent (LCE)

- Long 40-Year Mine Life: Proven and Probable Mineral Reserve Estimate totaling 287.65 Mt at an average grade of 1,149 ppm Li containing 0.330 Mt of lithium or 1.759 Mt of LCE

- Initial Project: Phase 1 Capital Cost $1.537 billion for production capacity of 13,000 tpa LCE

- Designed for Expansion: Phase 2 $0.651 billion for 28,000 tpa LCE, and Phase 3 $1.336 billion for 41,000 tpa LCE; Project expansions are capitalized with Project cash flow

- Low Operating Cost: average operating cost $8,223/t of Li2CO3 produced, or $2,766/t after sales of surplus sodium hydroxide (NaOH)

- After-tax IRR of 17.1% at $24,000/t Li2CO3: $3.01 billion after-tax net present value (NPV) at 8% discount rate and a 17.1% after-tax internal rate of return (IRR), using price assumptions of $24,000/t for Li2CO3 and $600/dry metric tonne (dmt) for NaOH

VANCOUVER, BC, April 29, 2024 /PRNewswire/ – Century Lithium Corp. (TSXV: LCE) (OTCQX: CYDVF) (Frankfurt: C1Z) (Century Lithium or the Company) is pleased to announce the results of a National Instrument 43-101 (NI 43-101) feasibility study (Feasibility Study, FS or Study) completed on its 100% owned Clayton Valley Lithium Project (Project) in Nevada, USA. The Feasibility Study was prepared by Wood Group USA, Inc. (Wood) and Global Resource Engineering, Ltd. (GRE). All currency amounts in this news release are presented in U.S. dollars.

“Century Lithium is proud to present our Feasibility Study. The Study indicates our Project has robust economics, made possible with our unique chlor-alkali and DLE processes” commented Bill Willoughby, President, and CEO. “Completion of the Study marks a major milestone for the Company and is the result of the dedicated work and efforts of our team of employees and consultants.”

“Our process technology was developed by way of many trials and successes at our Pilot Plant in Amargosa Valley. As one of the few lithium-focused Pilot Plants in North America, we continue to operate safely and recently passed two years of testing. The data generated to date supports the Feasibility Study, and we continue to test various conditions and ideas to improve our process flow sheet,” said Bill Willoughby.

With the Feasibility Study completed, the Company will now direct its focus on engineering and permitting. The Company is concurrently advancing discussions with government agencies, strategic partners, and other interested parties to provide funding to advance the Project and maximize the value to the Company’s shareholders that is reflected in the FS.

FEASIBILITY STUDY SUMMARY

The information in the following tables highlight the Project’s production and economic summaries.

|

Production Summary |

||||

|

Phase |

Years |

Mine tonnes per day (tpd) |

Li2CO3 (tpa) |

Capital Cost (B$) |

|

1 |

1-5 |

7,500 |

13,000 |

$1.537 |

|

2 |

6-10 |

15,000 |

28,000 |

$0.651 |

|

3 |

11+ |

22,500 |

41,000 |

$1.336 |

|

Economic Summary |

Units |

Amount |

|

Operating Costs (average) |

$/t |

8,223 |

|

Operating Costs (average w/NaOH credit) |

$/t |

2,766 |

|

After-tax NPV @ 8% Discount Rate |

$ billion |

3.01 |

|

After-tax IRR |

% |

17.1 |

RESOURCE AND RESERVES

The Mineral Resource and Reserve Estimates for the Project were updated for the Feasibility Study and built using geologic data and 1,318 lithium assays from 45 core holes drilled between 2017 and 2022. The constrained Measured and Indicated Resource Estimate is 1,207.33 Mt with an average grade of 957 ppm lithium and contains 1.155 Mt of Li or 6.148 Mt of LCE. The Proven and Probable Mineral Reserve Estimate was derived from the constrained Mineral Resources and contains 287.65 Mt with an average grade of 1,149 ppm lithium and contains 0.330 Mt of Li or 1.759 Mt of LCE and reflects an increase of 74.6 Mt and 0.48 Mt LCE compared to the 2021 Mineral Reserve Estimate. The Mineral Resources were generated with a pit shell that encompasses all mineralized material within the Property excluding all areas that will be used for Project infrastructure and placement of tailings, waste, and low-grade material.

|

Mineral Resource Estimate |

||||

|

Domain |

Tonnes Above Cut-off (millions) |

Li Grade (ppm) |

Li Contained (million t) |

LCE (million t) |

|

Measured |

858.38 |

990 |

0.849 |

4.524 |

|

Indicated |

348.95 |

875 |

0.305 |

1.625 |

|

Measured & Indicated |

1,207.33 |

957 |

1.155 |

6.148 |

|

Inferred |

119.03 |

827 |

0.098 |

0.524 |

|

The effective date of the Mineral Resource Estimate is December 15, 2022. The QP for the estimate is Ms. Terre Lane, MMSA, an employee of GRE and independent of Century. The Mineral Resources are constrained by a pit shell with a 200 ppm Li cut-off and density of 1.505 g/cm3. The cut-off grade considers an operating cost of $16.90/t mill feed, process recovery of 83% and a long-term lithium carbonate price of $20,000/t. The Mineral Resource estimate was prepared in accordance with CIM Definition Standards (CIM, 2014) and the CIM Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines (CIM, 2019). Mineral Resource figures were rounded. One tonne of lithium = 5.323 tonnes lithium carbonate. Mineral Resources are inclusive of Mineral Reserves. |

||||

|

Mineral Reserve Estimate |

||||

|

Domain |

Tonnes Above Cut- off (millions) |

Li Grade (ppm) |

Li Contained (million t) |

LCE (million t) |

|

Proven |

266.39 |

1,147 |

0.306 |

1.626 |

|

Probable |

21.26 |

1,174 |

0.025 |

0.133 |

|

Proven & Probable |

287.65 |

1,149 |

0.330 |

1.759 |

|

The effective date of the Mineral Reserve Estimate is December 15, 2022. The QP for the estimate is Ms. Terre Lane, MMSA, an employee of GRE and independent of Century. The Mineral Reserve estimate was prepared in accordance with CIM) Definition Standards (CIM, 2014) and the CIM Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines (CIM, 2019). Mineral Reserves are reported within the final pit design at a mining cut-off of 900 ppm. The cut-off grade considers a mine operating cost of $1.98/t, a process operating cost of $14.27/t milled, a G&A cost of $0.65/t milled, process recovery of 83% and a long-term lithium carbonate price of $20,000/t. The cut-off of 900 ppm is an elevated cut-off selected for the mine production schedule as the elevated cutoff is 4.5 times higher than the break-even cut-off grade. Mineral Reserve figures have been rounded. One tonne of lithium = 5.323 tonnes lithium carbonate. Mineral Resources are inclusive of Mineral Reserves. |

||||

PROCESS METALLURGY & CHLOR-ALKALI PLANT

Metallurgical testing through 2020 focused on using sulfuric acid (H2SO4) to extract lithium from the clay. In late 2020, testing shifted to hydrochloric acid (HCl) for its improved compatibility with the deposit’s chemistry. These benefits included higher lithium extractions, lower reagent consumptions, significantly better filtration of solids, and the ability to utilize certain DLE technologies in the recovery and concentration of lithium from the leach solutions.

A key component of the Project with chloride-based leaching is a chlor-alkali plant. The chlor-alkali plant provides the ability to produce the key reagents HCl and NaOH on-site from the electrolysis of a sodium chloride (NaCl) solution. A chlor-alkali plant represents a greater capital investment relative to that of a sulfuric acid plant but has important environmental and economic benefits for the sustainability of the Project. These benefits include replacing the purchase and transportation of sulfur with regionally sourced salt, and a reduction in emissions and the physical footprint of the operation with dryer, non-sulfate tailings.

Additionally, the chlor-alkali plant will generate significant quantities of NaOH surplus to the Project’s operational needs and therefore available for sale. The chlor-alkali plant will utilize modern electrochemical cell technology thereby producing membrane grade sodium hydroxide without the energy consumption and environmental problems of older technologies. The surplus amounts of NaOH are inherent to the operation of the plant and the sales represent a significant offset to the Project’s operating costs.

PILOT PLANT

In 2021, Century Lithium constructed a Pilot Plant in Nevada to leach one tonne per day of lithium clay and produce a high-grade lithium chloride solution which is processed off-site at Saltworks Technologies, Inc. (Saltworks), at their Richmond, British Columbia processing plant to make battery-quality Li2CO3. To maximize lithium recovery, the Company purchased the license rights and pilot-stage equipment to DLE an ion-exchange-based process and incorporated it into the Pilot Plant. The DLE license is held in perpetuity and royalty free by the Project.

Throughout its Pilot Plant program, the Company has sought improvement in its process methods. The Company obtained a provisional patent in 2023 with the U.S. Patent and Trademark Office, U.S. Department of Commerce. The provisional patent is titled System and Method for Extracting Lithium from Clay and Other Materials in a Chloride Solution Using Individualized Pretreatments. The patent pending process encompasses the Company’s flowsheet and protects its methods of leaching lithium-bearing solids and handling solutions, precipitates, and residues.

LITHIUM EXTRACTION, RECOVERY & Li2CO3 PRODUCTION

A lithium recovery of 78% is used in the Feasibility Study, based on the data collected in over two years of operations at the Pilot Pant.

- Feed material grades averaged 1,100 ppm

- Leach solution samples varied from 200 to 320 ppm Li

- Lithium extractions averaged 88% and varied from 80 to 95%

- DLE lithium recoveries were typically above 90%

- 10% of the lithium in solution is retained in the moisture remaining in the tailings

Extraction rates do not account for losses downstream and are only indicative of the potential overall recovery. Work at the Pilot Plant continues to focus on reducing losses of lithium to tailings. A small loss of lithium from processing the DLE product solutions into Li2CO3, and the recycling of process solutions to the DLE and leach areas is anticipated.

During 2022 and 2023, Saltworks processed the DLE product solutions from the Pilot Plant and made battery-quality Li2CO3 at greater than 99.5% purity. Modifications at the Pilot Plant in mid-2023 increased lithium solution grades to over 14 grams per liter which simplified the flowsheet and eliminated the evaporation stage for production of Li2CO3.

PRODUCTION PLAN

The Project’s production plan comprises three equal phases of production rate increases, Phase 1 and Phase 2 production rates are maintained over five years each and Phase 3 is maintained for 30 years. This approach was selected to reduce capital exposure and risk by dividing the Project’s production schedule into realistic phases of construction and equipment installation. The plan fully utilizes the Project’s Mineral Reserve.

Phase 1 includes all work required to implement the Initial Project Plan including all necessary mining and processing infrastructure. The Phase 2 cost estimate focuses on an expansion within the footprint of Phase 1. Phase 3 development includes an additional processing plant and facilities not built in the previous phases and allows for a fourth phase of expansion.

LITHIUM CARBONATE AND SODIUM HYDROXIDE SALES PRICES

A price of $24,000/t of Li2CO3 is used in the Feasibility Study as the Project base case. This price is selected as a conservative mid-point between current market prices which are under $20,000/t Li2CO3 and forecast prices obtained from Benchmark Mineral Intelligence which are in the range of $23,000 to $39,000/t Li2CO3 during Phase 1 and $29,000 to $31,000/t Li2CO3 thereafter (Benchmark Mineral Intelligence, Lithium Forecast Q1 2024). The sales price is free on board (FOB) the Project site for battery quality Li2CO3.

NaOH is a product of the chlor-alkali process and a sales price of $600/dmt FOB the Project is used in the Feasibility Study as the Project base case. Based on the material mass balance, it is expected that surplus NaOH will be available for sale at rates of 120,000 to 360,000 dmt per annum, depending on Project Phase. This price is based on a February 2023 market study by Global Exchange and Trading, Inc. where it was determined the Project’s surplus NaOH can be readily sold in the western U.S. which currently relies heavily on imports arriving at west coast ports.

CAPITAL COST ESTIMATE

The basis for the capital cost estimate follows AACE Class 3 for feasibility studies. Contributors to the estimates are GRE (mining), Wood (process plant and infrastructure), ThyssenKrupp Nucera (chlor-alkali plant) and Century Lithium (property information and owners’ costs). The capital cost estimates by phase are summarized as follows.

|

Installed Capital Costs |

Initial Phase 1 ($M) |

Expansion Phase 2 ($M) |

Expansion Phase 3 ($M) |

|

Mining & Site Preparation |

$64 |

$7 |

$27 |

|

Process Facilities |

$517 |

$205 |

$477 |

|

Chlor-Alkali Plant |

$496 |

$336 |

$496 |

|

Buildings, Services & Infrastructure |

$130 |

$5 |

$42 |

|

Indirect & Owners Costs |

$234 |

$72 |

$190 |

|

Contingency |

$96 |

$27 |

$105 |

|

Total Capital Cost |

$1,537 |

$651 |

$1,336 |

|

Notes: Totals may not sum due to rounding, Contingency and site Indirects for chlor-alkali plant is included in the Chlor-Alkali Plant line item, contingency for mining is included in the Contingency line item, indirect costs for mining are not included in the Indirects and Owner’s Costs line item |

|||

The Phase 2 capital costs represent the expansion of the process facilities and infrastructure established in Phase 1. The Phase 3 capital costs support an additional processing plant and facilities not built in the previous phases. In the Project schedule, a 2-year period is allocated for the time to construct and commission each phase.

Sustaining capital over the life of the Project is estimated at $315 million for tailings facility expansion and equipment replacements. These costs are in addition to the expansion capital costs shown above.

OPERATING COST ESTIMATES

The following information highlights the operating cost estimates for each phase in dollars per tonne of Li2CO3, before and after deducting sales of surplus NaOH.

|

Initial Phase 1 (7,500 tpd mill feed) |

$ (000s)/y |

$/t mill feed |

$/t LCE |

|

Mining |

$13,754 |

$5.43 |

$1,205 |

|

Processing and G&A |

$57,515 |

$21.01 |

$4,428 |

|

Chlor-Alkali Plant |

$61,787 |

$22.57 |

$4,757 |

|

Total Operating Cost |

$133,056 |

$49.01 |

$10,390 |

|

Less NaOH Sales (FOB mine) |

$78,272 |

$28.95 |

$6,026 |

|

Net Operating Cost |

$54,784 |

$20.06 |

$4,364 |

|

Note: Totals may not sum due to rounding |

|||

|

Expansion Phase 2 (15,000 tpd mill feed) |

$ (000s)/y |

$/t mill feed |

$/t LCE |

|

Mining |

$24,901 |

$4.26 |

$766 |

|

Processing and G&A |

$82,018 |

$14.98 |

$3,157 |

|

Chlor-Alkali Plant |

$105,138 |

$19.20 |

$4,047 |

|

Total Operating Cost |

$212,057 |

$38.44 |

$7,970 |

|

Less NaOH Sales (FOB mine) |

$142,350 |

$26.00 |

$5,479 |

|

Net Operating Cost |

$69,707 |

$12.44 |

$2,491 |

|

Note: Totals may not sum due to rounding |

|||

|

Expansion Phase 3 (22,500 tpd mill feed) |

$ (000s)/y |

$/t mill feed |

$/t LCE |

|

Mining |

$22,064 |

$2.70 |

$561 |

|

Processing and G&A |

$119,945 |

$14.60 |

$3,078 |

|

Chlor-Alkali Plant |

$151,325 |

$18.43 |

$3,884 |

|

Total Operating Cost |

$293,334 |

$35.73 |

$7,523 |

|

Less NaOH Sales (FOB mine) |

$213,525 |

$25.99 |

$5,479 |

|

Net Operating Cost |

$79,809 |

$9.74 |

$2,044 |

|

Note: Totals may not sum due to rounding |

|||

ECONOMIC MODEL AND SENSITIVITY

The cash flow model is developed using base prices of $24,000/t for Li2CO3 and $600/dmt for NaOH.

|

Average Annual Values |

Units |

Initial Phase 1 |

Expansion Phase 2 |

Expansion Phase 3 |

|

Li2CO3 Sales |

t |

11,885 |

26,753 |

39,098 |

|

NaOH Sales |

dmt |

130,488 |

237,250 |

355,875 |

|

Gross Sales |

$ million |

$282.4 |

$635.7 |

$929.0 |

|

Before-tax Cash Flow |

$ million |

$231.3 |

$553.3 |

$825.3 |

Lithium carbonate sales are the average over each Phase including ramp up to the stated production rate. Gross sales are revenues from Li2CO3 and NaOH sales are before operating costs and after royalty. Before-tax Cash Flow is gross sales minus operating costs. Taxes are applied at federal, state and county rates after allowances for amortization, depletion, and depreciation only. Possible tax credits under the U.S. Inflation Reduction Act or other programs are not included.

The Project base case generates a 17.1% after-tax IRR and NPV-8% of $3.01 billion. These results are sensitive to changes in operating assumptions including the sales price of Li2CO3.

- At 75% of the base case, or $18,000/t LCE, the after-tax NPV@ 8% is $1.52 billion, and the after-tax IRR is 12.9%.

- At 125% of the base case, or $30,000/t LCE, the after-tax NPV@ 8% is $4.47 billion, and the after-tax IRR is 20.9%.

- For every $1,000/t change in the price of lithium carbonate, the after-tax NPV@8% changes by about $250 million.

|

Project Sensitivity |

Units |

75 % |

Base Case |

125 % |

|

Lithium Price |

$/t LCE |

$18,000 |

$24,000 |

$30,000 |

|

NPV-8% |

$ billion |

$1.52 |

$3.01 |

$4.47 |

|

IRR |

% |

12.9 |

17.1 |

20.9 |

PROJECT ADVANCEMENT

The Company has completed multiple environmental studies in advance of permitting and is examining ways to optimize power requirements and incorporate alternative energy solutions.

The recommendations of the FS include continuing the permitting process, engaging with governmental agencies and other parties, and proceeding with detailed engineering to further advance the Project.

Among these steps, the Company has contacted the U.S. Department of Energy’s (DOE) Loan Programs Office (LPO) and plans to initiate the pre-application process under the Title Seven Clean Energy Financing program when the Feasibility Study report is complete.

CONFERENCE CALL

Century Lithium will host a live webcast and conference call for analysts and investors on Monday, April 29, 2024, at 11:00 am ET (8:00 am PT), followed by a question-and-answer session.

To register for the webcast, link here: https://events.6ix.com/preview/century-lithium-announces-positive-feasibility-study

A replay of the webcast will be available on our website shortly following the conclusion of the conference call.

QUALITY ASSURANCE

The data in this news release was prepared in accordance with NI 43-101 standards by the following Qualified Persons (QP).

- Terre Lane, Principal Mining Engineer, GRE, is an independent QP as defined by NI 43-101 and has reviewed and approved the contents of this news release and verified by site visits and personal examination the information and original documents that relate to preparation of the Mineral Resource Estimate, Mineral Reserve Estimate, mine plan, mine capital and operating cost estimation, economic analysis, and marketing.

- Hamid Samari, Principal Geologist, GRE, is an independent QP as defined by NI43-101 and has reviewed and approved the contents of this news release and verified by site visits and personal examination the information and original documents that relate to preparation of the description of the deposit, geological setting, and mineralization, deposit type, exploration, drilling, sample preparation, analyses and security, and data verification.

- Todd Fayram, Senior Vice President Metallurgy, Century Lithium, is a non-independent QP as defined by NI 43-101 and has reviewed and approved the contents of this news release and verified by site visits and personal examination the information and original documents that relate to preparation of the description of metallurgical testing, lithium recovery, and design operation and results of the Pilot Plant.

- Alan Drake, Manager – Process Engineering, Wood, is an independent QP as defined by NI 43-101 and has reviewed and approved the contents of this news release and verified by site visits and personal examination the information and original documents that relate to preparation of the description and estimates related to recovery methods.

- Haiming (Peter) Yuan, PE, PhD, Principal Geotechnical Engineer, WSP USA Environment & Infrastructure Inc., is an independent QP as defined by NI 43-101 and has reviewed and approved the contents of this news release and verified by site visits and personal examination the information and original documents that relate to preparation of the description related to infrastructure, environment and permitting.

- Paul Baluch, Technical Director, Civil, Wood, is an independent QP as defined by NI 43-101 and has reviewed and approved the contents of this news release and verified by personal examination the information and original documents that relate to preparation of the description and estimates of infrastructure.

- Farzad Kossari, Cost Estimating Manager, Wood, is an independent QP as defined by NI 43-101 and has reviewed and approved the contents of this news release and verified by personal examination the information and original documents that relate to preparation of the description and summary of capital and operating cost estimates.

Further information about the Project, including a description of the key assumptions, parameters, description of sampling methods, data verification and quality assurance (QA) / quality control (QC) programs, methods relating to Mineral Resources and Mineral Reserves and factors that may affect those estimates will be contained in a NI 43-101 Technical Report on the Feasibility Study of the Clayton Valley Lithium Project. Following Section 3.4 of NI 43-101 the report will be available on SEDAR+ and on the Company’s website within 45 days of the date of this news release.

ABOUT CENTURY LITHIUM CORP.

Century Lithium Corp. is an advanced stage lithium company, focused on developing its 100%-owned Clayton Valley Lithium Project in west-central Nevada, USA. Century Lithium recently completed a Feasibility Study on its Clayton Valley Lithium Project and is currently in the permitting stage, with the goal of becoming a domestic producer of lithium for the growing electric vehicle and battery storage market.

ON BEHALF OF CENTURY LITHIUM CORP.

WILLIAM WILLOUGHBY, PhD., PE

President & Chief Executive Officer

centurylithium.com

NEITHER THE TSX VENTURE EXCHANGE NOR ITS REGULATION SERVICES PROVIDER ACCEPTS RESPONSIBILITY FOR THE ADEQUACY OR ACCURACY OF THE CONTENT OF THIS NEWS RELEASE.

Cautionary Note Regarding Forward-Looking Statements

This release contains certain forward-looking statements within the meaning of applicable Canadian securities legislation. In certain cases, forward-looking statements can be identified by the use of words such as “plans”, “expects” or “does not anticipate”, or “believes”, or variations of such words and phrases or statements that certain actions, events or results “may”, “could”, “would”, “might” or “will be taken”, “occur” or “be achieved” and similar expressions suggesting future outcomes or statements regarding an outlook.

Forward-looking statements relate to any matters that are not historical facts and statements of our beliefs, intentions and expectations about developments, results and events which will or may occur in the future, without limitation, statements with respect to the potential development and value of the Project and benefits associated therewith, statements with respect to the expected project economics for the Project, such as estimates of life of mine, lithium prices, production and recoveries, capital and operating costs, IRR, NPV and cash flows, any projections outlined in the Feasibility Study in respect of the Project, the permitting status of the Project and the Company’s future development plans.

These and other forward-looking statements and information are subject to various known and unknown risks and uncertainties, many of which are beyond the ability of the Company to control or predict, that may cause their actual results, performance or achievements to be materially different from those expressed or implied thereby, and are developed based on assumptions about such risks, uncertainties and other factors set out herein. These risks include those described under the heading “Risk Factors” in the Company’s most recent annual information form and its other public filings, copies of which can be under the Company’s profile at www.sedarplus.com. The Company expressly disclaims any obligation to update-forward-looking information except as required by applicable law. No forward-looking statement can be guaranteed and actual future results may vary materially. Accordingly, readers are advised not to place reliance on forward-looking statements or information. Furthermore, Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

SOURCE Century Lithium Corp.

Nevada

Nevada Supreme Court Orders Gruden’s Case Against NFL To Arbitration

Photo by Ethan Miller/Getty Images

In a May 14, 2024 Order, the Supreme Court of the State of Nevada reversed a lower court’s holding that former Las Vegas Raiders head coach Jon Gruden did not have to arbitrate his claims against the NFL and Commissioner Roger Goodell arising out of his October 2021 forced resignation. Gruden now faces the prospects of pursuing an arbitration process ostensibly – but not necessarily – controlled by Goodell.

The District Court Goes For Gruden

Gruden was forced to resign after the revelation of emails in which he engaged in what the NFL described in a legal brief as “racist tropes and misogynistic and homophobic slurs.” At the time, Gruden was in the fourth year of a 10-year, $100 million contract, the largest contract ever for an NFL coach.

Notwithstanding the fact Gruden and the Raiders quickly reached a confidential settlement concerning Gruden’s departure, in November 2021, Gruden sued the NFL and Goodell (but not the Raiders) in the Eighth Judicial District Court in Clark County, Nevada, alleging principally that the defendants had intentionally and tortiously interfered with Gruden’s contract with the Raiders by allegedly leaking the problematic emails.

In January 2022, the NFL filed separate motions to dismiss the case and to compel the matter to arbitration. In its motion to compel, the NFL relied on two provisions of Gruden’s employment agreement. First, Gruden agreed generally to be “bound by the Constitution, Bylaws, and rules and regulations of the NFL.” Based on this provision, the NFL argued that Gruden is bound by Section 8.3(E) of the NFL Constitution, which provides the Commissioner authority to arbitrate a dispute “that in the opinion of the Commissioner constitutes conduct detrimental to the best interests of the League or professional football.” Second, Gruden’s contract contained an arbitration provision requiring that “all matters in dispute between Gruden and [the Raiders], including without limitation any dispute arising from the terms of this Agreement, shall be referred to the NFL Commissioner for binding arbitration, and his decision shall be accepted as final, conclusive, and unappealable.”

On May 26, 2022, the District Court denied both motions ruling from the bench. The court held that the NFL’s first argument on the motion to compel failed because, as pointed out by Gruden, invoking this authority would supposedly require Goodell to predetermine the outcome of the arbitration. Second, the court determined that the NFL’s reliance on the arbitration provision contained in Gruden’s contract was misplaced because it only covered disputes between Gruden and the Raiders, which are not a party to the litigation. The District Court’s opinion was later expanded on in an order written by Gruden’s counsel and signed by the District Court, a process permitted by Nevada’s rules.

The Nevada Supreme Court Reverses

The Nevada Supreme Court, in a 2-1 decision, determined that the District Court made numerous errors in its decision. First, the Court held that Gruden failed to prove that his settlement with the Raiders extinguished the relevant arbitration clauses because he did not offer the settlement agreement as evidence in the case and because arbitration clauses are presumed to survive contract termination. Second, the Court determined that Gruden’s contract incorporated the NFL Constitution by reference because Gruden agreed to be bound by it and because it was available to him. Third, the Court found that Gruden’s claims were within the scope of Section 8.3(e) because “[w]hether judged from the perspective of Gruden’s emails becoming public or the NFL Parties’ alleged leaking of those emails, the conduct-detrimental to the NFL or professional football requirement appears satisfied.” Fourth, the Court rejected Gruden’s argument that the arbitration agreement was procedurally unconscionable, finding that he “was the very definition of a sophisticated party” in negotiating his employment agreement. Fifth, concerning substantive unconscionability, while the Court expressed some concern about Goodell potentially serving as the arbitrator in a matter in which he is a defendant, “it is not clear that Goodell will act as arbitrator.” Moreover, the Court noted, “issues of arbitrator bias are reviewable post-arbitration.” Finally, the Court rejected Gruden’s argument that the arbitration agreement is “illusory” because the NFL can amend it unilaterally, noting that the NFL’s ability to do so is restrained by the implied covenant of good faith and fair dealing inherent in every contract.

For all of these reasons, the Court reversed the District Court’s decision and remanded the case with instructions to grant the NFL’s motion requesting that the case be compelled to arbitration.

Justice Linda Marie Bell, writing in dissent, argued that the arbitration agreement did not apply to Gruden because he is no longer an employee of the Raiders. Additionally, Justice Bell believed that incorporation of the NFL Constitution into Gruden’s contract was procedurally unconscionable because Gruden had no choice but to accept it and, at 447 pages, it dwarfed the terms of Gruden’s 7-page employment agreement.

Gruden’s Call

It will soon be up to Gruden to decide whether to file an arbitration with Goodell pursuant to the provisions of the NFL Constitution. Goodell is unlikely to preside over the arbitration, out of the concern that any decision he makes could then be vacated by a court on the ground of bias. Goodell has historically taken one of three routes in these situations: (1) he designates internal NFL counsel to preside over the matter (often General Counsel Jeff Pash); (2) he designates an outside attorney who formerly worked for the NFL or one of its clubs to be arbitrator (Harold Henderson and Bob Wallace, for example); or (3) in high-profile matters where judicial scrutiny is likely, he designates a respected arbitrator or attorney to serve. The most likely choice would be an attorney or arbitrator with labor and employment expertise and some NFL ties but not so much as to create a strong impression of bias.

The last option is what Goodell chose in 2022 when the NFL appealed an arbitrator’s decision to suspend Cleveland Browns quarterback DeShaun Watson for six games, much less than the 14 games the NFL wanted. Goodell had the right under the collective bargaining to hear the appeal but instead appointed Peter Harvey, a former Attorney General for New Jersey and NFL consultant as arbitrator. The parties settled for an 11-game suspension before any appeal was heard.

Gruden is more than two years into this legal battle and, given his pugnacious reputation, is unlikely to drop the case now. Moreover, given the judicial scrutiny Commissioner Goodell’s involvement has already received, it is more likely that Gruden will be able to have his claims fairly considered by a neutral (or near neutral) party.

Nevada

Those wolves that were seen in Nevada? They weren’t wolves

The wonder of an unconfirmed sighting of a gray wolf pack that could have marked the return of the species to Nevada was cut short when genetic testing revealed they weren’t wolves at all.

Rather, the animals that wildlife officials spotted near Merritt Mountain in Elko County were coyotes, a common sight across the Silver State in both rural and urban settings.

Two independent genetic labs found that the hair, fecal and urine samples collected from the scene in early March were a 99.9 percent match for coyotes, the Nevada Department of Wildlife said.

The last time a wolf was seen in Nevada was 2017. Prior to that, one hadn’t been spotted in the state since 1922.

“We understand the significance of such sightings and the importance of accurate identification,” NDOW director Alan Jenne said in a statement.

Scientists spotted the coyotes when taking stock of Nevada’s moose population, and the state agency was working with the U.S. Fish and Wildlife Service to make a plan to ensure the wolf pack’s safety if the animals turned out to be wolves and stayed within state borders.

Federally, gray wolves became endangered in 1974, when only about 600 of them still roamed the lower 48 states. Though Nevada wildlife officials said the state isn’t known to be historic wolf habitat, the Center for Biological Diversity estimates there could have been upward of 2 million of them when European settlers arrived in North America.

“We appreciate the diligence of our biologists, assisting laboratory personnel and the public’s cooperation throughout this process and we will continue to monitor the area for any indication of wolf presence,” Jenne said in a statement.

Contact Alan at ahalaly@reviewjournal.com. Follow @AlanHalaly on X.

Nevada

Latest COVID strain doesn’t appear to pose a threat in Las Vegas Valley

Wastewater is an early warning system for COVID and other diseases, and a collaborative effort in Nevada appears to be the first in the nation to detect a new strain of the disease — known as FLiRT.

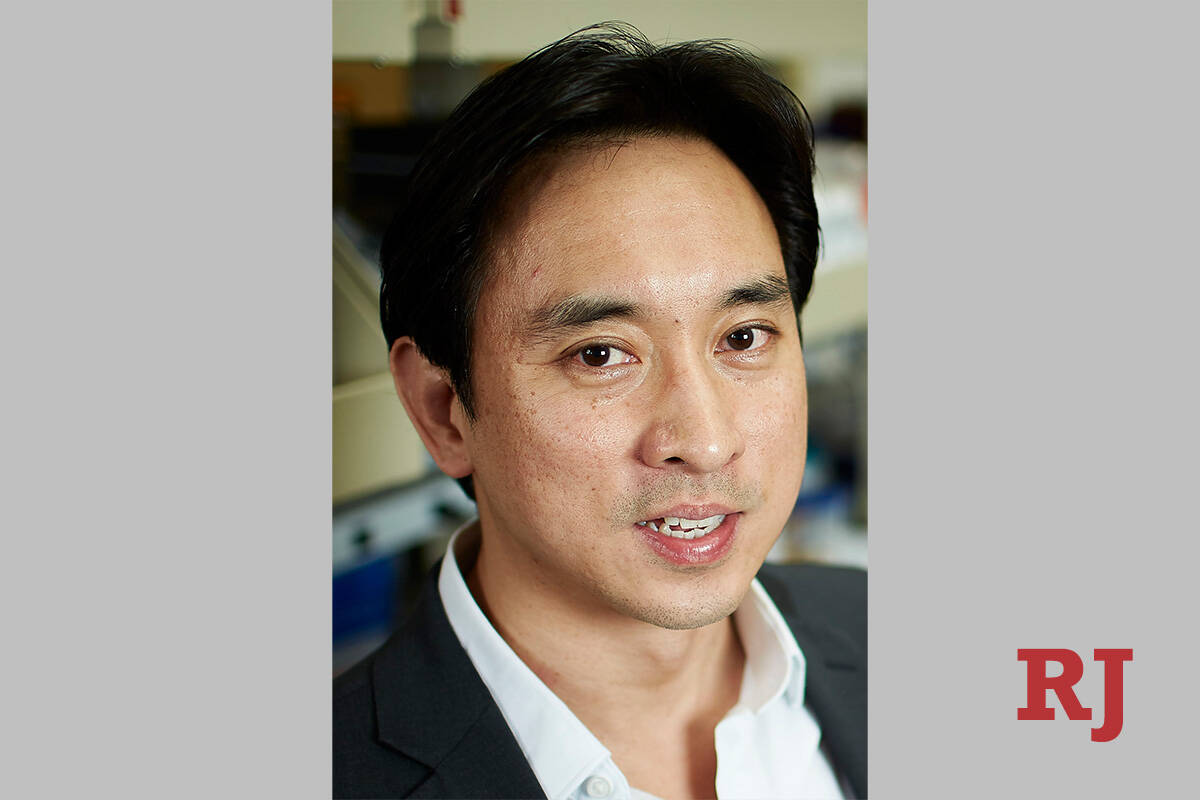

“We detected it as early as March 29,” said UNLV Professor Dr. Edwin Oh, director of the UNLV lab that monitors wastewater in southern and northern Nevada, adding that his check of various websites from labs across the country that do such wastewater monitoring, indicates UNLV was first in finding the new variant.

The goal of the wastewater surveillance and research is to determine if any new strain of the constantly evolving disease — that once killed 25,000 Americans a week at its height in 2020 — might pose a problem for humans.

“So far it does not look like it (FLiRT) poses any major threats,” Oh said of the the two variants — KP.1 and KP.2. — that are mutations of FLiRT.

“We nerd out a lot on the different pathogens and variants,” Oh said of his crew that includes UNLV undergrads and wastewater treatment plant operators. About 15 different sites are checked weekly in Clark County and three or four sites in Northern Nevada.

The effort is to warn and protect the community from COVID variants that could raise the risk of major sickness potential.

Genetic material from the virus that causes COVID-19 can be found in human waste even when individuals have no symptoms. Tracking the amount of viral genetic material (viral load) in wastewater is an emerging method of monitoring increasing and decreasing trends of the virus in communities.

Wastewater surveillance has been ongoing for years. The most recent variant that raised eyebrows was JN.1 around Christmas time, Oh said. “It had about 50 mutations and a lot of us were concerned that it might bring added risk to the immunocompromised (population) or the vaccine resistant (population).”

The wastewater monitoring project is a collaboration between Southern Nevada Health District, Southern Nevada Water Authority, Desert Research Institute and UNLV.

Contact Marvin Clemons at mclemons@reviewjournal.com.

-

Politics1 week ago

Politics1 week agoHouse Dems seeking re-election seemingly reverse course, call on Biden to 'bring order to the southern border'

-

World1 week ago

World1 week agoSpain and Argentina trade jibes in row before visit by President Milei

-

Politics1 week ago

Politics1 week agoFetterman says anti-Israel campus protests ‘working against peace' in Middle East, not putting hostages first

-

World1 week ago

World1 week agoGerman socialist candidate attacked before EU elections

-

News1 week ago

News1 week agoUS man diagnosed with brain damage after allegedly being pushed into lake

-

World1 week ago

World1 week agoGaza ceasefire talks at crucial stage as Hamas delegation leaves Cairo

-

Politics1 week ago

Politics1 week agoRepublicans believe college campus chaos works in their favor

-

Politics1 week ago

Politics1 week agoConservative beer brand plans 'Frat Boy Summer' event celebrating college students who defended American flag

/cloudfront-us-east-1.images.arcpublishing.com/gray/KXRBKGNNUZDYDIEBK7CLZ6ZHCA.png)