Business

China mira hacia México para satisfacer al mercado de EE. UU.

Invoice Chan nunca había puesto un pie en México, y mucho menos en la solitaria franja desértica del norte del país donde apruptamente decidió construir una fábrica de 300 millones de dólares. Pero eso le parecía un detalle insignificante, en medio de la presión para adaptarse a una economía world que cambia con rapidez.

Period enero de 2022 y la empresa de Chan, Man Wah Furnishings Manufacturing, enfrentaba grandes dificultades al trasladar los sofás de sus fábricas en China a los clientes en Estados Unidos. Los precios de envío se habían disparado. Washington y Pekín estaban enfrascados en una feroz guerra comercial.

Man Wah, una de las empresas de muebles más grandes de China, estaba ansiosa por fabricar sus productos en el lado norteamericano del Pacífico.

“Nuestro principal mercado es Estados Unidos”, dijo Chan, director ejecutivo de la subsidiaria mexicana de Man Wah. “No queremos perder ese mercado”.

Ese mismo objetivo explica por qué decenas de importantes empresas chinas están invirtiendo agresivamente en México, aprovechando un acuerdo comercial expansivo con América del Norte. Siguiendo un camino forjado por las empresas japonesas y surcoreanas, las firmas chinas están estableciendo fábricas que les permiten etiquetar sus productos como “Hecho en México”, y luego los transportan en camiones libres de impuestos a Estados Unidos.

El interés de los fabricantes chinos en México forma parte de una tendencia más amplia conocida como nearshoring o deslocalización cercana. Las empresas internacionales están acercando la producción a los clientes para limitar su vulnerabilidad a los problemas de transporte y las tensiones geopolíticas.

La participación de las empresas chinas en este cambio muestra la suposición cada vez más profunda de que la brecha que divide a Estados Unidos y China será una característica duradera de la próxima fase de la globalización. Sin embargo, también revela algo elementary: más allá de las tensiones políticas, las fuerzas comerciales que unen a Estados Unidos y China son aún más poderosas.

Las empresas chinas no tienen intención de abandonar la economía estadounidense, que sigue siendo la más grande del mundo. En cambio, están estableciendo operaciones dentro del bloque comercial de América del Norte como una forma de suministrar bienes a los estadounidenses, desde productos electrónicos hasta ropa y muebles.

El estado fronterizo mexicano de Nuevo León se ha posicionado para cosechar las recompensas de esa tendencia. Dirigido por un impetuoso gobernador de 35 años, Samuel García, el estado ha cortejado la inversión extranjera mientras busca mejorar las carreteras para facilitar el paso a los cruces fronterizos.

García asistió recientemente al Foro Económico Mundial en Davos, Suiza, para reclutar más empresas.

“Nuevo León está teniendo un alineamiento planetario geopolítico”, declaró el gobernador durante una entrevista en la capital del estado de Monterrey, dentro del palacio de gobierno, un laberinto de grandes habitaciones con techos altos y balcones que miran hacia los picos irregulares de la Sierra Madre. “Estamos recibiendo muchos asiáticos que quieren venir al mercado estadounidense”.

Desde que García asumió el cargo en octubre de 2021, se han invertido casi 7000 millones de dólares en inversiones extranjeras en Nuevo León, lo que convierte a ese estado en el mayor receptor después de Ciudad de México, según la Secretaría de Economía de México.

En 2021, las empresas chinas fueron responsables del 30 por ciento de la inversión extranjera en Nuevo León, solo superadas por Estados Unidos con el 47 por ciento.

Parte de este dinero está financiando fábricas que harán productos terminados para la venta en Estados Unidos. Pero buena parte de esas operaciones se centran en una remodelación más amplia de la cadena de suministro world.

A medida que la pandemia interrumpió la industria china y colapsó los puertos, las empresas con fábricas en Estados Unidos sufrieron escasez de piezas manufacturadas en Asia. Ahora muchas compañías exigen que sus proveedores establezcan plantas en América del Norte o corren el riesgo de perder su negocio.

Lizhong, un fabricante chino de rines para automóviles, está construyendo la primera fábrica de la compañía fuera de Asia en un parque industrial en Nuevo León. Los principales clientes de Lizhong, incluidos Ford y Common Motors, presionaron a la empresa para que abriera una fábrica en América del Norte, según Wang Bing, su gerente common para México.

Una empresa de Corea del Sur, DY Energy, que fabrica componentes para equipos de construcción, está considerando el norte de México para instalar una fábrica cerca de un importante cliente en Texas.

“Después de pasar por la pandemia y la disaster de la cadena de suministro debido al cierre de China por la covid, a muchos fabricantes norteamericanos les gustaría eliminar el riesgo”, dijo Sean Website positioning, ejecutivo de DY Energy con sede en Seattle.

“La globalización ha terminado”, declaró. “Ahora se habla de local-ización”.

César Santos ha hecho una apuesta sustancial respecto a que esos pronunciamientos resulten ciertos.

Santos, un abogado corporativo de 65 años, dirige una empresa secundaria como desarrollador en Monterrey, una ciudad industrial en auge llena de restaurantes de lujo, centros comerciales resplandecientes y spas.

Hace una década, se le acercó un desarrollador en Los Ángeles que representaba a una empresa electrónica china que estaba contemplando construir una fábrica en México. Santos controlaba un activo de gran interés: una parcela de 849 hectáreas.

Salpicada de cactus, la propiedad se encontraba a menos de 241 kilómetros de la frontera con Texas. Mientras los estados vecinos luchaban con la violencia vinculada al narcotráfico, Nuevo León tenía una reputación de seguridad. El estado contaba con una fuerza laboral altamente calificada, dada la presencia de universidades que producían en masa graduados de ingeniería, entre ellas el Tec de Monterrey, a menudo denominado “el MIT de México”.

La tierra había sido el rancho ganadero de su familia cuando Santos period un niño, el escenario de aventuras a caballo. Ahora ve una oportunidad lucrativa para convertirlo en un parque industrial.

Hizo un viaje a China, en un tren de alta velocidad desde Shanghái hasta la ciudad de Hangzhou, frente a un lago, para reunirse con Holley Group, que había construido un parque industrial para empresas chinas en Tailandia.

“China period un país que había desarrollado todo muy rápido”, dijo Santos. “Estaba realmente asombrado”.

Para 2015, se unió a Holley y otro socio chino para forjar una empresa conjunta, Hofusan Actual Property. Planean una purple de almacenes y fábricas frente a un lodge y apartamentos temporales para gerentes visitantes, además de más de 12.000 hogares para trabajadores.

El Grupo Holley envió a Jiang Xin para supervisar la empresa. Antes había trabajado en el proyecto de esa empresa en Tailandia. Pero México representaba una propuesta diferente.

“Las empresas chinas no tenían thought de México, y las únicas cosas que sabíamos eran cosas malas, cosas peligrosas”, dijo Jiang. “Luego vino Trump”.

Cuando asumió la presidencia en 2017, Donald Trump exigió que las empresas estadounidenses abandonaran China. Para 2018, estaba aplicando fuertes aranceles a cientos de miles de millones de dólares en importaciones chinas.

“Lo de los aranceles nos ayudó”, dijo Jiang. “Las empresas chinas querían más opciones. Y nosotros somos una de sus opciones”.

Cuando Chan comenzó a contemplar la posibilidad de operar en México en el otoño de 2021, otras 27 empresas chinas ya habían asegurado terrenos dentro del parque Hofusan. Solo quedaba un predio grande.

Man Wah ya había respondido a los aranceles construyendo una fábrica en Vietnam y usándola con el fin de manufacturar productos para el mercado estadounidense. Pero el precio altísimo de los envíos empobreció esa estrategia.

Cada mes, Man Wah estaba moviendo 3500 contenedores de 12 metros a través del Pacífico desde Vietnam. De repente, los viajes que costaban 2000 dólares se incrementaron 10 veces más.

Chan usó la plataforma de redes sociales china, WeChat, para conectarse con Jiang. Sus preguntas eran contundentes. ¿Qué tan pronto podría Man Wah comenzar la construcción? (Inmediatamente). ¿Cómo estaban las carreteras? (No eran excelentes, pero estaban mejorando). ¿Había algún restaurante chino auténtico en los alrededores? (No).

En cuestión de semanas, Man Wah se comprometió a comprar el terreno. En enero de 2022, Chan firmó el contrato antes de abordar un vuelo a México, dejando atrás a su esposa y sus dos hijos en la ciudad china de Shenzhen.

Mientras se construye la nueva fábrica, Man Wah ya ha comenzado a producir sofás en una pequeña planta cercana que alquilaron.

Incluso antes de ubicar el sitio temporal, Chan cargó 70 contenedores llenos de maquinaria y materias primas en China y los puso en un barco con destino a México.

“Siempre hacemos las cosas rápido”, dijo. “No te preocupes por nada, solo hazlo”.

Man Wah se preocupa por algunas cosas: contratar suficientes trabajadores y cultivar proveedores locales.

La empresa tiene planes de fabricar cerca de 900.000 piezas de mueblería al año en México. Eso requerirá contratar y retener a 6000 trabajadores.

Man Wah está acostumbrado a operar en China y Vietnam, donde los sindicatos independientes están básicamente prohibidos y la gente de las zonas rurales acude a las zonas industriales en busca de trabajo.

En Nuevo León, la tasa de desempleo es de 3,6 por ciento. El aumento de la inversión ha desencadenado una feroz competencia por los trabajadores.

Las empresas astutas han cortejado a sus empleados con extras como comidas de calidad y transporte al trabajo. Pero Man Wah y otras empresas chinas responden a los jefes en China, que están condicionados hacia el ahorro mientras piensan en los trabajadores como fácilmente remplazables.

Encontrar proveedores locales también es un desafío. Según los términos del acuerdo comercial de América del Norte, los fabricantes deben emplear porcentajes mínimos de piezas y materias primas de la región para calificar para el acceso libre de impuestos a los demás países del bloque.

Hace tres años, Lenovo, el fabricante chino de computadoras, abrió una nueva fábrica en Monterrey dedicada a fabricar servidores, los dispositivos que almacenan datos para la computación en la nube.

Hasta el año pasado, Lenovo traía un componente essential, las llamadas placas base, desde una fábrica en China. Pero a medida que se intensificaron los problemas de transporte internacional, la empresa cambió a un proveedor en la ciudad mexicana de Guadalajara.

Lenovo también dejó de importar materiales de embalaje de China y, en cambio, los compra en México.

Pero continúa importando muchos componentes clave de China, desde dispositivos de memoria hasta cables especializados.

“No existe una cadena de suministro para estas cosas en México”, dijo Leandro Sardela, director de operaciones occidentales de la empresa.

Peter S. Goodman es corresponsal de economía mundial, con sede en Nueva York. Antes fue corresponsal de economía mundial con sede en Londres y corresponsal económico nacional en Nueva York durante la Gran Recesión. También trabajó en The Washington Publish como jefe de la oficina de Shanghái. @petersgoodman

Business

Disneyland costumed character employees vote to unionize

Disneyland Resort employees who portray costumed characters such as Mickey Mouse or Cinderella have voted to unionize under the Actors’ Equity Assn.

The unit, which consists of 1,700 people, voted 953 in favor of unionization and 258 against, Actors’ Equity said Saturday night on the social media platform X. Of the votes tallied, 79% were pro-union.

The results of the vote, overseen by the National Labor Relations Board, come after a three-day election period in which employees, known as “cast members” in Disney parlance, placed their votes at three polling sites in Disneyland. The employees announced their intent to unionize in February.

“This is an incredible victory, and we appreciate all the support over the past several weeks. We’re excited about the next phase,” said Actors’ Equity Assn. President Kate Shindle in a statement. “These cast members are both pro-union and pro-Disney, and they’re looking forward to meeting with their employer across the bargaining table in a good faith effort to make both the work experience and the guest experience better.”

The workers regularly don full-body costumes of well-known animated Disney characters. They also portray so-called lookalike characters, such as the Disney princesses, in which the actors’ faces are exposed while performing. These employees work at meet-and-greets in the parks, perform in parades and are part of dining experiences in the Disneyland Resort hotels.

“While voting is complete, there are still steps in the process prior to the election being certified, so it is premature for the company to comment on the results,” said Disneyland spokesperson Jessica Good in a statement. “Whatever the outcome, we respect that our cast members had the opportunity to have their voices heard.”

Organizers said prior to the election that a top priority was creating a healthier and safer working environment for these workers, who often endure injury and discomfort due to the physical nature of their jobs.

Employees can get accidentally injured during guest interactions, such as when a child jumps on a costumed character out of excitement, or intentionally hurt. A recent social media trend emerged in which guests distract employees wearing full-body costumes, then try to twist or aggressively move their heads around.

The Disneyland Resort employees in the characters and parades departments now join their counterparts in Walt Disney World in Florida in being part of a union. Most of the rest of the Disneyland Resort workforce, including custodians, ride operators and merchandise clerks, among others, are already unionized.

The organizing effort comes as the Walt Disney Co. plans to invest $60 billion over 10 years into its “experiences” division, which includes the theme parks, resorts, cruise line and merchandise. That division has proved to be a cash cow for the company; last year, it brought in about 70% of Disney’s operating income.

At Disneyland Resort, that investment will result in what company Chief Executive Bob Iger called the biggest expansion of the parks since the addition of Disney’s California Adventure, which opened in 2001. The plan, known as DisneylandForward, will result in at least $1.9 billion in development and could include new attractions alongside restaurant, retail and hotel space.

The plan calls for changes to the park’s zoning, allowing the company more freedom to mix attractions, theme parks, shopping, dining and parking. While the plan doesn’t specify which attractions will be added to the resort, company officials have floated ideas including immersive “Avatar,” “Frozen” and “Tron” experiences.

Times staff writers Christi Carras and Ryan Faughnder contributed to this report.

Business

On a Hollywood studio lot, a new New York comes to life

Last summer, when the Hollywood writers’ strike had shut down film and television production, a crew of scenic painters at the legendary Fox Studio Lot took advantage of the lull to mess up New York City.

Work had recently been completed on a new set of façades meant to mimic Manhattan streets, but the result was too pretty and clean. Even the smooth gray concrete curbs looked suspiciously fresh.

“After the curbs were perfectly poured, we had a gentleman with a jackhammer come in here and chip away at them,” said Gary Ehrlich, president of studio operations. “It was slightly heartbreaking to see.”

Today, the curbs are suitably beaten up, with dings and black smears as if tires had been rubbing against them for decades. Fire escapes look corroded and other metal fixtures such as banisters have been coated to look old or rusty, while walls appear water-stained. A patina of age has settled over this faux city.

A film crew gets ready for a shoot at the new New York set at Fox Studios in Los Angeles on March 26, 2024. The new set that is different from conventional backlot façades because it has stages inside the New York “buildings” where filming can take place.

The painstaking besmirchment of New York Street was one more twist in the long saga of one of filmdom’s most famous outdoor sets. Looming near the front gate like an adult-sized playhouse, an earlier version of the set and now the new one have long served notice to visitors that they have arrived at a movie studio that is itself a leading character in Hollywood lore.

Its lineage is suitably rich in Hollywood flavor: In 1967 Fox was preparing to shoot the film version of “Hello, Dolly!,” a Tony-award winning musical set in 1890s New York City that ran for years on Broadway. The script included a spectacular outdoor parade with thousands of extras, and studio executives determined that it would be impossible to shoot on location in New York because the city had changed too much.

Fox production designer John DeCuir, who had already won Academy Awards for his design of “The King and I” and “Cleopatra,” came up with a streetscape that required more than 500 workers to labor for four months to build. The $2.25-million price tag made it the most costly movie set built to date, the UPI news service reported at the time.

It required more than 300,000 feet of board lumber and 22 miles of telephone wire strung between poles, the way it was in old New York. A painted 11-story office building façade obscured the view of the Century Plaza Hotel looming next to the lot, according to Barbra Archives, which chronicles the career of “Hello, Dolly!” star Barbra Streisand.

Barbra Streisand marches with a band in a scene from the 1969 romantic comedy “Hello, Dolly!” filmed on Fox’s New York set in Century City.

(John Springer Collection / Getty Images)

Dominating the street was a replica of an elevated train station and a steam locomotive acquired from a sugar plantation in Hawaii, where it had been used to transport workers.

On July 16, 1968, the Valley Times reported, “The parade stretching one-fifth of a mile and comprised of 675 persons in 16 units passed through a crowd of 3,108 film extras” in period costumes. Among the performers were the UCLA marching band and the Budweiser Clydesdales. The director was actor-dancer Gene Kelly.

As impressive as the set was, it was intended to be temporary, said Michael Whetstone, a production designer who worked on building the new version of New York Street.

“It was supposed to be torn down but wasn’t because it was too expensive” to remove, he said. At the time the studio was reeling from financial setbacks including a $30-million loss on “Hello, Dolly!,” according to the New York Times.

Maintenance and prop makers James Scobie, left, and Norm Greene, work on the façade of the new New York set at Fox Studios .

The set enjoyed a second, money-making act in the years that followed as Fox rented it out for use on pictures that included Warner Bros.’ comedy “Up the Sandbox,” starring Streisand, and MGM’s musical “New York, New York,” starring Liza Minnelli and Robert De Niro. Among the television shows that used it were “Charlie’s Angels” and “Moonlighting,” while Bruno Mars, Lady Gaga and other musicians used it for music videos.

But a few years ago, with the set showing its age, the studio started considering its replacement, Ehrlich said. “It had been exposed to the elements for five decades and was past its useful life.”

Fox tapped Culver City architect Nathan Moore of House & Robertson Architects to design something sturdier.

Construction required 49 tons of rebar and more than 1,000 cubic feet of concrete. The set is held up by 260 tons of structural steel and backed inside with 4,400 square feet of catwalks. Lighting and other electrical functions are supported with 21,000 square feet of conduit and wire, allowing productions to hook up to house power instead of rolling in generators. The set also had to comply with building codes and be tracked by city building inspectors.

The new New York Street was made to look like the city in the mid 20th century, a decision that required detailed craftsmanship such as window heads and sills that would have been carved out of wood in years past but were instead fabricated out of plastic foam and finished with plaster. Windows were installed to be easily replaced so productions can break them when scenes call for it.

Whetstone oversaw the project and, as part of his research, made several trips to New York, spending long hours on foot trying to get a sense of how light plays on buildings at night.

“I was literally walking Lower Manhattan from 10 p.m. to 4 in the morning taking pictures,” he said.

Where the original “Hello, Dolly!” set was based on a commercial section of 1890s New York suitable for a parade, Fox elected to make the new set feel like a neighborhood from a later era.

“It’s more Lower Manhattan, more Bowery,” Whetstone said. “Definitely the Lower East Side.”

A film crew member waits to set up for a shoot at the new New York set.

While the set is “a default vision of New York City,” said Whetstone, it also is intended to stand in for any major city. Through the years, Fox’s New York Street has subbed for Chicago, Washington, D.C., and Pasadena.

Even though improving camera technology through the years has made it easier to shoot on location, there are reasons filmmakers keep shooting on studio lots, said Jason E. Squire, entertainment podcaster and professor emeritus at USC School of Cinematic Arts.

As filming equipment and cameras got lighter and more portable, the more free-flowing New Wave cinema that emerged in the late 1950s and ’60s employed provocative camerawork.

“This liberation led to people shooting off the studio lot,” Squire said. “Filmmakers wanted to get away from the studio.”

But it has remained expensive to shoot a large-scale production in the real world with all the vehicles, equipment and personnel required to be transported and managed on-site.

“One of the key decisions early in any production is whether to build sets on a lot or shoot in a real location,” Squire said. “That depends on how intricate the sequences are going to be, how intimate. It’s a judgment call and a money call, and the money usually wins.”

Shooting behind studio gates also prevents uncomfortable collisions between fantasy and reality.

“On the lot you don’t have interference from civilians,” Squire said. “You can control traffic, you can control lighting. All of the equipment is at your beck and call.”

Whetstone recalled having to flee location shooting in downtown L.A.’s Arts District when working on Season 1 of “New Girl,” a Fox television comedy starring Zooey Deschanel that premiered in 2011.

“We started out shooting in downtown Los Angeles, and by the end of our fifth night shoot we had angered so many of the neighbors around in the community that we ended up building downtown L.A. on the Fox lot,” Whetstone said.

Gary Ehrlich, president and general manager of studio operations at Fox Studio Lot, shows off the scaffolding for lighting inside one of the buildings in Fox’s new New York Street set.

The makeover of New York Street is in addition to a planned $1.5-billion upgrade of the Fox Studio Lot announced last year by Fox Corp. that is to include more soundstages and offices. Fox Corp. retained ownership of the lot when Walt Disney Co. bought most of 21st Century Fox’s entertainment assets in 2019.

The upgrades come as the real New York mounts an aggressive effort to lure TV and movie producers from L.A. by building new studios and soundstages.

On New York Street in Los Angeles, Fox also was able to transform the set behind the façades, adding 4,000 square feet of interior space that makes it easier to meld outdoor and indoor action. The studio declined to reveal exactly how much the new multimillion-dollar set cost, but Fox wants it to stand for another half-century at least.

“This project was approached not just as temp architecture but as something more permanent,” Whetstone said. “We want this to last a long time.”

Business

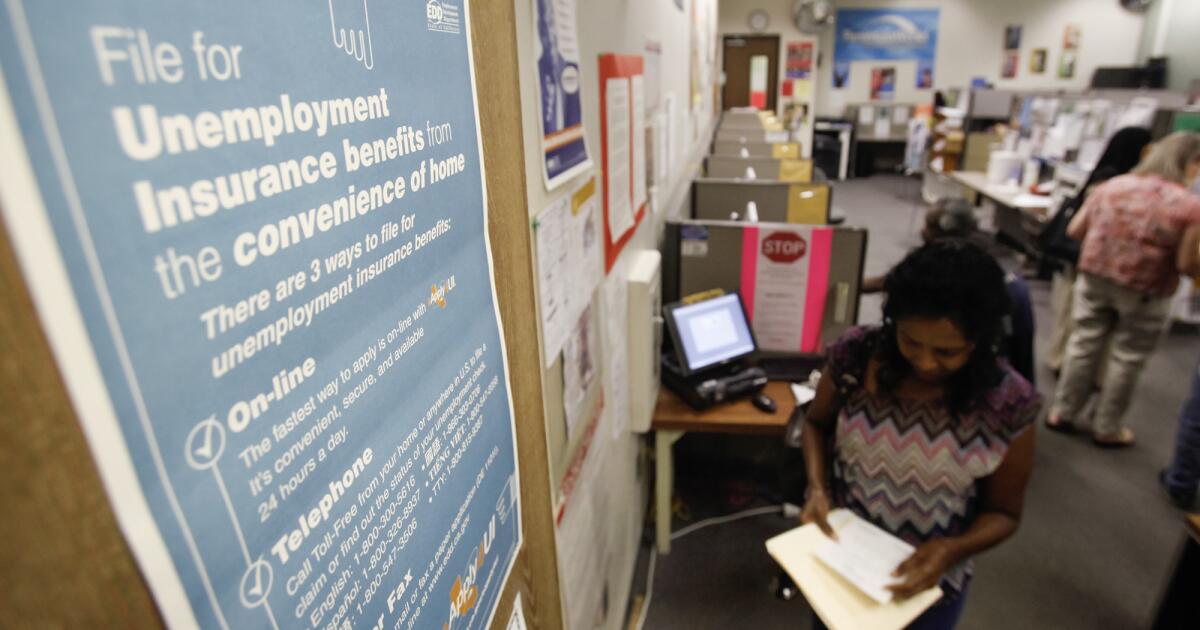

As job growth in California falls back, unemployment rate remains highest in the country

California posted another month of anemic job growth in April, keeping the state’s unemployment rate the highest in the country, 5.3%, the government reported Friday.

Statewide, employers added a net of just 5,200 jobs in April, down from 18,200 in March, according to California’s Employment Development Department.

Nationwide, employers added 175,000 jobs in April and 315,000 in March. The U.S. unemployment rate in April was 3.9%.

Major sectors of California’s economy — including manufacturing, information and professional and business services — showed job losses last month, and job opportunities aren’t as plentiful as before, even as the number of unemployed workers in the state has risen by 164,000 over the last 12 months.

In California, there were 140 unemployed workers for every 100 job openings in March, according to federal statistics released Friday. Less than two years ago, there were about two openings for every jobless person.

Carol Jackson, an unemployed worker in South Los Angeles, says she has been pounding the pavement for months, hoping to make use of her recently minted associate degree in web management and database administration. But despite sending her resume to at least 100 employers, she has not had a single interview.

“I can tell you that California is pretty brutal now,” said Jackson, 57.

Hiring in California has been lagging behind national trends, with one notable exception. The state’s healthcare and social assistance sector added 10,100 jobs last month, bringing the gains over the last 12 months to about 155,000. That’s 75% of all new jobs added since April 2023.

Hospitals and doctors’ offices have been bulking up, but the fastest growth has been at outpatient centers, home healthcare firms, nursing facilities and, especially, social assistance, which includes vocational rehabilitation and child day-care services.

“Healthcare is the big gorilla in the room; it dominates everything,” said Mark Schniepp, director of the California Economic Forecast in Santa Barbara, adding that it’s likely to keep growing robustly with new and expanded medical facilities across the state.

Leisure and hospitality businesses added 3,100 jobs last month. The gains included employment at hotels and restaurants — despite the added stress employers are feeling from a minimum wage increase to $20 an hour for fast-food workers that went into effect April 1.

While there are fears of layoffs as the food industry adopts technology to replace workers, California’s restaurants are getting a lift from a pickup in tourism. The leisure sector overall is close to fully recovering from the deep losses caused by the COVID-19 pandemic.

Public-sector payrolls also held up well last month, increasing by 2,600. Thus far, state and local government jobs seem to be showing little effects from California’s massive budget deficits.

“But clearly that will be another factor,” said Sung Won Sohn, economics professor at Loyola Marymount University in Los Angeles.

Sohn and other economists worry that there are national, cyclical and state-specific threats to California’s employment and broader economic outlook.

Key pillars of the state’s economy continue to struggle.

Motion picture producers and other employers in the information sector show few signs of breaking out of the hiring doldrums, despite the film industry’s resolution of labor strikes last fall. Los Angeles’ motion picture and recording studio industries were down by 13,400 employees, or 12%, in April compared with the same month a year earlier. And many workers in the industry say conditions do not appear to be improving.

Large parts of the farm economy in the Central Valley remain sluggish, in part due to rising costs, tighter financial conditions and ongoing climate challenges.

Despite strong investments in artificial intelligence, layoffs have persisted at high-tech firms in the Bay Area and elsewhere. Scientific and technical companies shed jobs last month, and employment at computer systems design work and related services has been gradually declining.

Nationally, economists expect job growth to slow in the coming months, the result of persistently high interest rates and an expected pullback from consumers. The outlook is particularly dim in California.

“On the ground, there are several signs of even more slowdowns,” said Michael Bernick, an employment lawyer at Duane Morris in San Francisco and former director of the state’s EDD. Among them, he said, “small businesses continue to struggle statewide with higher prices and tightened consumer spending.”

He and other experts have a similar refrain about what ails the state: high costs, excessive regulation and unaffordable home prices, among other factors.

“We just have real challenges here in California that other states don’t face,” said Renee Ward, founder of Seniors4Hire.org, a Huntington Beach-based organization that helps older workers find employment.

She said the number of job seekers registered with her service has jumped 26% so far in 2024 from a year ago.

-

Finance1 week ago

Finance1 week agoSpring Finance Forum 2024: CRE Financiers Eye Signs of Recovery

-

World1 week ago

World1 week agoIndia Lok Sabha election 2024 Phase 4: Who votes and what’s at stake?

-

Politics1 week ago

Politics1 week agoBiden’s decision to pull Israel weapons shipment kept quiet until after Holocaust remembrance address: report

-

News1 week ago

News1 week agoThe Major Supreme Court Cases of 2024

-

World1 week ago

World1 week agoA look at Chinese investment within Hungary

-

Politics1 week ago

Politics1 week agoTales from the trail: The blue states Trump eyes to turn red in November

-

World1 week ago

World1 week agoBorrell: Spain, Ireland and others could recognise Palestine on 21 May

-

Politics1 week ago

Politics1 week agoFox News Politics: No calm after the Stormy